Neochrome Paint

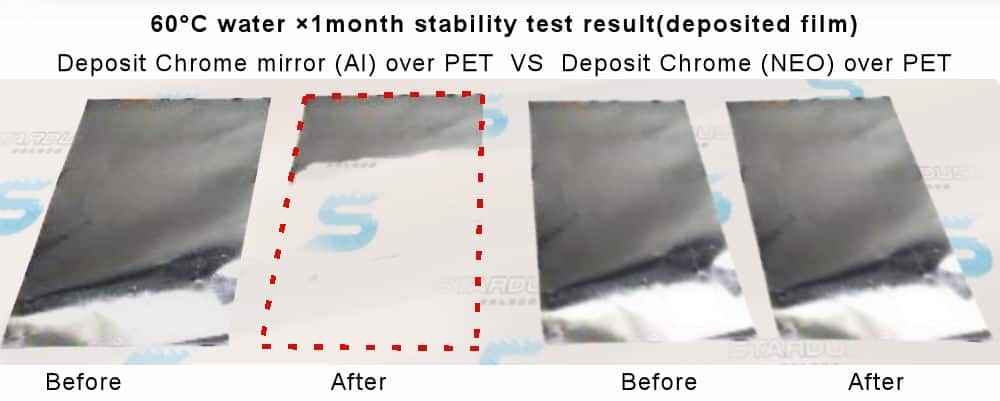

Based on a rare metal, NeoChrome produces a mirror-like effect similar to that of silver (metallization through silver plating). However, unlike silver, which is sensitive to oxidation and UV radiation, or even aluminum, NeoChrome offers the advantages of easy processing and very high resistance to corrosion from water, weather, or UV radiation.

Alternative to Traditional Chrome Plating

NeoChrome is an alternative to certain types of chrome plating, as the use of hexavalent chromium (Chromium IV) has been prohibited in Europe since September 2024 (due to regulatory constraints, highly restrictive legislation, permit applications, etc.).

NeoChrome is not an alternative to hard chrome, but rather an alternative to the "chrome look" because the paint uses no toxic products, is economical and simple to apply, and, above all, can be chromed onto any type of surface.

Composition: Solvent-based paint, free of toxic products and heavy metals. Contains no chromium. Flammable products. Follow safety instructions.

Varnishing

Varnishing can be done with any glossy, colorless varnish, without any difficulty or special technique, and without losing the reflective effect.

Results vary depending on the type of varnish. Generally, UHS automotive paints produce excellent results. By baking for a long time or drying for several days at room temperature, any varnish can be applied without special techniques, maintaining the reflective effect, for a result close to silver plating.

SILAX P760 Chrome Primer: A transparent, ultra-fine, and fluid product. SILAX guarantees varnish adhesion and preserves the mirror finish of chrome paint very well, without prolonged drying or heating.

Application steps:

1 – Black or White base coat (drying time: 20-60 minutes)

2 – Ceramic varnish (drying time: 12 hours)

3 – NeoChrome (drying time: 1 hour) or (10 minutes drying + application of a coat of SILAX)

4 – 2K Ceramic varnish or other 2k varnish (drying time: 1 hour) or a candy color 10-30 min dry than 2k varnish

Areas of Application

NeoChrome is a chrome-effect paint suitable for professional and industrial applications, in the automotive industry, decorative architectural areas, and for both indoor and outdoor use.

NeoChrome is a highly transparent and conductive paint that can also be applied to windows. It is also suitable for certain glossy, hard plastics and resins.

Product type:

Single-component solvent-based paint

Second step of the NeoChrome paint system (base/chrome/lacquer)

Application method:

Apply by dabbing with a sponge or foam brush

Spray (for best results) with an airbrush from 0.2 mm or with a pneumatic spray gun up to 1.4 mm

Substrate:

Apply over 2K gloss ceramic varnish ST8900X and allow to dry for at least 12 hours.

Can be applied to all types of prepared substrates and materials, directly onto glass and certain plastics (ABS, PET, PS).

Apply with a spray gun or airbrush:

Step 1 – On a white, gray, or black base coat (paint or primer), apply a two-component ultra-hard and ultra-glass varnish. Allow the varnish to fully cure for several days. The best results are achieved with our ultra-fast-curing ST8900X ceramic paint with a minimum drying time of 12 hours.

Step 2 – Degrease with a cloth and/or a water-based antistatic cleaner to ensure a perfectly clean surface. Then apply the NeoChrome paint in 2 or 3 thin coats, approximately 1 minute apart. The ideal application temperature is 15 to 25°C. Avoid application above 25°C.

NeoChrome paint is extremely sensitive to the presence of various contaminants, such as silicone. We recommend thoroughly degreasing with a degreaser.

It is very important to apply very thin coats and wait until the chrome paint layer has dried and evaporated before applying another coat. This will ensure a flawless chrome look.

Optional: Drying/Firing:

We recommend 1 hour to 7 days at 20°C or 20 minutes to 3 hours at 60°C before varnishing. IR drying is possible in 5-10 minutes.

Step 3 – Apply a gloss varnish. For an ultra-strong and glossy finish, we recommend ST8900X varnish. The varnish is applied quickly and easily with an airbrush or spray gun without losing the mirror effect. Apply one or two very thin coats of varnish, allowing two minutes for drying, followed by a full, glossy coat. Allowing the product to dry for several days at room temperature, or baking it for several hours at 60°C, or firing it briefly at a high temperature (80-150°C) will achieve optimal results and maintain the mirror effect.

There are three drying methods available before applying the high-gloss paint to maintain 100% of the mirror effect:

- Dry for 5 days at 20°C

- Dry for 3 hours at 60°C

- Dry for 10 minutes at 20°C + SILAX application (2 thin coats)

Background color: We recommend a white background color for the best result.

On a black background, the result will be slightly darker.

Questions and Answers

? - Can color be added to this chrome, for example, to create a gold chrome finish?

► - Any color can be achieved by adding concentrated Candy ink to the clearcoat. Or, after the clearcoat has dried, apply a pre-mixed Candy ink over it and then clearcoat again.

? - Can any clearcoat be used over Neochrome?

► Any clear, gloss clearcoat can be used.

? - Do I need to polish between coats?

► Polishing is not necessary when using the NeoChrome paint system.

Application Advice with a Sponge

Use a low-density sponge or foam brush and moisten it with enough product to apply a thick coat in one go. Move from left to right across the surface.

Lay the product on the surface, avoiding crossing layers.

Allow the product to evaporate. After evaporation, it's possible to apply a touch-up coat if there's a product shortage. Applying a new coat can cover the defects.

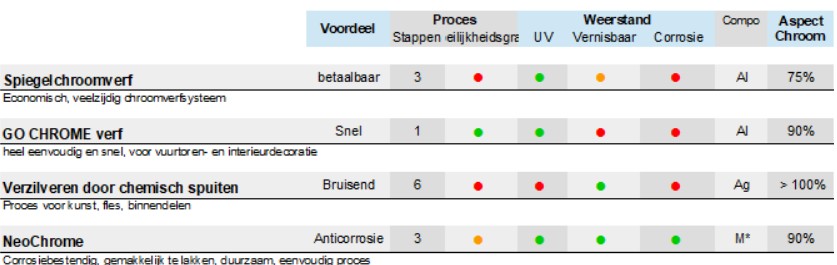

What are the differences with Chrome to Go paint?

Chrome to Go paint is another type of chrome paint that distinguishes itself by the ease with which it provides a glossy finish in a single coat, in one step, without primer or varnish. It is used for artwork or interior decoration, or for the inside of car headlights. It is a paint that cannot be varnished and is not abrasion-resistant. NeoChrome is a three-step paint system, making it easy to paint and offering high resistance to wear and corrosion for all types of applications.

What are the differences with mirror chrome paint?

Traditional mirror chrome paint is suitable for all kinds of projects, is very economical to use, and is applied in three steps. It requires some drying time and is a difficult painting technique.

NeoChrome paint is innovative because of its durability, allowing it to be used outdoors for extended periods. Moreover, it's easy to varnish, thus protecting against wear and tear.

Spiegelverf: Een potentiële innovatie voor de spiegelindustrie

Spiegelverf: Een potentiële innovatie voor de spiegelindustrie

Het is mogelijk om een spiegel te creëren met NeoChrome-verf. Hiervoor is een perfect schoon raam nodig, dat kan worden gereinigd met een reinigingsmiddel of zelfs gerenoveerd met ceriumoxide om kalkaanslag en microkrassen te verwijderen. De verf biedt een lichtreflectie-index die vergelijkbaar is met die van zilver, het edelmetaal dat wordt gebruikt om spiegels te creëren door middel van chemische verzilvering. Het biedt echter een hogere kwaliteit, een lagere prijs, een veel eenvoudigere applicatie en anticorrosie- en anti-uv-eigenschappen, terwijl zilver gevoelig is voor zowel uv-straling als corrosie. Twee of drie ultradunne lagen zijn voldoende om een perfect heldere spiegel aan de binnenkant van het glas te creëren, die vervolgens kan worden bedekt met een beschermende, ondoorzichtige laag.

Veiligheid :

Ontvlambaar product, kan niet per vliegtuig worden verzonden, oplosmiddelhoudend (schadelijk). Bevat geen chroom (Cr) en derivaten daarvan of zorgwekkende stoffen (SVHC, CMR)

Kenmerken

Temperatuurbestendigheid : 125°C

Uiterlijk : grijsbruine vloeistof

Droge filmdikte : 2 µm

Opbrengst : 7-8 m² / Liter

Dichtheid : 0,88 kg/L

VOS >420g/L

MDSD pdf